The migration to our new CAD software is now complete. Solidworks was chosen for a range of reasons.

- Efficient 3D design

- Customer/Supplier Compatibility

- Built-In Applications

- Short Learning Curve

- After Sales Support

The migration to our new CAD software is now complete. Solidworks was chosen for a range of reasons.

West Pharmaservices are proud to announce we have passed our ISO 9001 audit and have been awarded the new ISO 9001:2015 certificate for the revised quality management standards.

West Pharmaservices are proud to announce we have passed our ISO 9001 audit and have been awarded the new ISO 9001:2015 certificate for the revised quality management standards.

Achieving the ISO 9001:2015 demonstrates our continued commitment to producing high quality products and delivering a consistent service to all our customers.

It also shows we are keen to invest time and money into new technology, staff, processes and procedures.

The ISO 9001:2015 certificate can be added to our long list of accreditation’s which includes our safe contractor status and CE Marking.

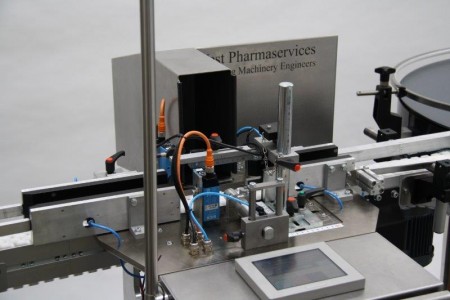

Key features of the WEST LRS 50:

Please contact us for more information.

Recent Comments